Founded in 1976 as a craft business, Pretty has evolved through a process of vertical integration that has enhanced quality and production efficiency.

Pretty Green Pathway: Digital and Green Industrial Transition

Pretty Mode was founded as a craft enterprise in Carpi in 1976, in the heart of one of the most important Italian textile districts. Pretty Cooperative Society, operating in the textile sector and specialized in subcontracting for major national and international brands, launched the project in October 2024 with the aim of fostering a corporate culture focused on sustainability and digital transition, in order to maintain and enhance the company’s competitiveness in line with evolving regulatory frameworks.

Specifically, the project called A Pretty Green Pathway aimed to:

- Integrate sustainability as a competitive advantage

- Improve internal skills

- Orient the corporate culture towards digital and ecological transition

To achieve these objectives, Pretty decided to rely on the consultancy Paradigmi srl, which organized the work in two main phases.

PHASE A – Identification of Specific Skills Needs

In the initial phase, a thorough analysis of the company’s organizational and production system was carried out, taking into account the management tools in use, the roles, and the skills of company personnel, in order to identify the need for specific competencies within the company, in line with the digital and ecological transition.

Specifically, this phase involved a compliance check, the setup of internal audits and audits at suppliers, the review of the internal organizational chart, and the social responsibility commitments towards clients and suppliers.

This process highlighted a small-sized company structure, with direct and informal relationships among members, often with overlapping roles. Additionally, the critical context of the fashion sector was considered, characterized by a contraction in consumption and a fragmented supply chain.

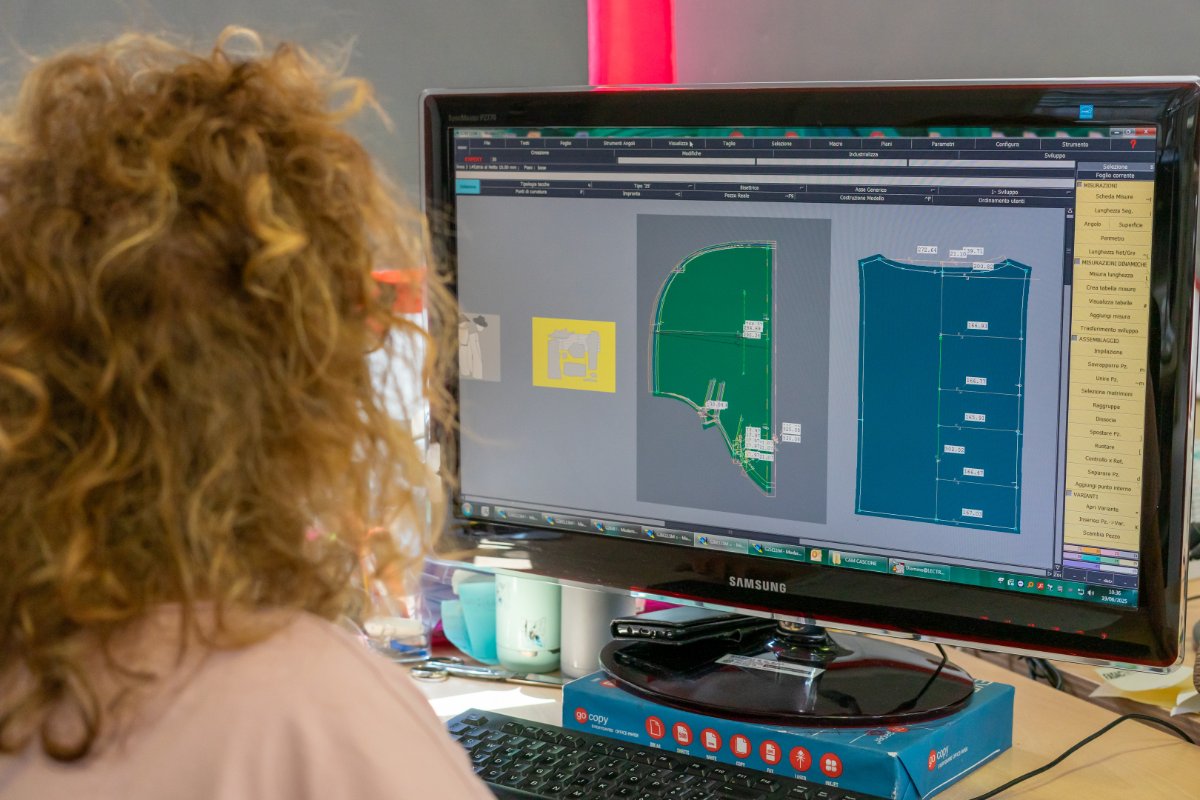

Particular importance was given to the analysis of documentation available from suppliers and to conducting inspections at their production sites. This activity served as the starting point to build awareness of issues occurring along the chain and to make the decision to internalize a production process.

PHASE B – Implementation of Actions to Reduce the Skills Gap Between Supply and Demand

In the actual operational phase, through the work of consultants (acting as temporary managers), existing procedures were streamlined, introducing the necessary adjustments to the relevant standards or guidelines in the areas of social responsibility, governance, and sustainability, with particular reference to the ISO 14001 standard and traceability issues based on standards provided by major clients. Regarding the Circular Economy asset, the environmental performance of work processes (including outsourced ones) was evaluated through data collection aimed at measuring circularity, at least in relation to the most immediately accessible aspects:

1. Reduction of resource inputs

2. Reduction of emission levels (pollutants and greenhouse gases)

3. Reduction of material/waste losses

4. Increase of renewable and recycled resource inputs

5. Maximization of product utility and durability

In relation to the two phases described above, the following actions were implemented:

1. Implementation of the Training Plan

The training plan included:

- Management Training: dedicated sessions to raise awareness and train company executives.

- Extended Training: scheduling courses for all company roles over the next three years, focusing on transversal skills and operational procedures.

The objective of the training was to help different managerial figures understand the importance of adopting an organic and systematic approach, ensuring that Sustainability is integrated into the value proposition, strategy, and business decision-making processes, taking into account the various stages of project implementation and the current socio-economic context.

This means adopting a comprehensive perspective on the levers and processes that generate value sustainably, thereby making the Sustainable Development Goals outlined in the United Nations 2030 Agenda concrete and achievable.

2. Analysis and Development of Procedures

The ISO 14001 standard framework was adopted as a reference to structure company procedures. The main phases were:

- Context Analysis: assessment of existing environmental practices.

- Procedure Development: creation of operational procedures to manage significant environmental aspects.

- Verification and Monitoring: implementation of systems to monitor the effectiveness of the procedures.

Within this scope, the skills required from internal personnel were also defined, in relation to the minimum standard requirements and with a view to continuous improvement, aiming to gradually transfer competencies such as carbon neutrality, waste valorization, and gender gap reduction.

ISO 14001 Certification

Currently, the company has not initiated third-party certification under ISO 14001. A testing period for the implemented procedures is planned, with the goal of evaluating the possibility of obtaining certification by 2027. Alternatively, the suitability and opportunity of other systems with a stronger social focus, such as SA8000 or another system, will also be considered.

The A Pretty Green Pathway Project represented a significant step for the company toward integrating sustainability into its corporate culture. The activities carried out laid the foundation for more conscious environmental management oriented toward continuous improvement, in line with industry challenges and market needs. Furthermore, the initiation of supplier verification actions led to the development of a new production department dedicated to garment assembly, allowing better control over part of the process and reducing the environmental impacts of semi-finished product transportation.